In today’s market, aluminum pricing isn’t just a line on an invoice — it’s a real measure of global volatility. Tariffs on imported aluminum have risen from 10% to 25%, with some hitting 50%, driving price swings of 30–35% per pound. That’s not policy on paper — it’s a direct cost that impacts every finished fuel tank on the market.

Even American-made manufacturers like AlumiTank aren’t immune to those pressures. Domestic mills have adjusted prices in response and raw material costs remain linked to the global market. But there’s a real difference in how those challenges get managed.

At AlumiTank, we’ve spent decades building a Midwest-based supply chain with partners in Illinois, Indiana and Wisconsin. We’re not waiting on offshore shipments or parked container ships to get raw materials. Most of our aluminum stock arrives within days — not weeks. We lock in conversion costs annually so we have predictability even when the base market price moves daily. Our strong relationships mean our suppliers keep the pipeline full, helping us avoid the shortages that rattled so many industries.

We also stock many of our most in-demand fuel tanks, making same-day or next-day shipping possible. That’s not something you get when you’re sourcing from overseas and hoping your order clears customs on time.

Here’s the truth: no one completely escapes rising costs in this market. But at AlumiTank, we’ve worked hard to absorb as much as we can without pushing big increases onto customers. Because to us, American-made doesn’t mean passing along every bump in the road — it means investing in stability, reliability and long-term partnerships.

This approach isn’t new. It’s how we’ve done business since 1989. Our family has been in trucking since 1938. We know downtime isn’t theoretical — it’s lost revenue, missed loads and frustrated customers. That’s why we pay close attention to every shift in pricing and policy so our customers don’t have to.

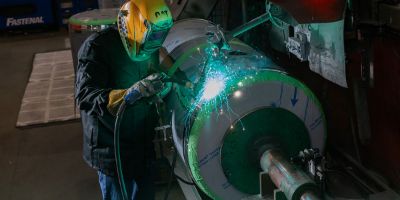

We believe a fuel tank should do its job without question. That’s why we build ours here, with American-sourced materials, American craftsmanship and decades of industry know-how. In a world where costs, supply chains and policies keep shifting, choosing American-made isn’t just about pride — it’s about making a smart, dependable investment in your business and the people who keep it running.